| Elevator Bucket-------D Series Bucket/ S Series Bucket /D/S Type Steel Bucket |

|

| |

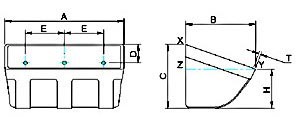

| d series bucket |

|

| In most cases, buckets stopped in use are caused by the heavy abrasion on the bucket mouth the tearing at the bucket mouth the bolt fitting due to collision in the running. Our D bucket design will relieve such situation in use extend the life of the bucket. The unique design has made an appropriate thickness reduction on the bottom which requires a lower intensity,the saved raw material will be used to increase the thickness of the bucket mouth the area around bolt holes. In this way, the buckets has higher intensity can become more wear-resistant without increasing the total weight. This design has been approved by test widely used by leading conveying equipment manufacturers in North America. |

| Usage: |

|

1.Suitable for high-speed centrifugal discharge.

2.Recommended minimum bucket spacing: width of the bucket projection "B"+25mm, which can be appropriately reduced according to elevator capacity requirement.

3.Recommended elevator velocity ≤ 2.5m/ s.

4.Recommend using"Z-Y+10%" as usable capacity for engineering purpose. |

| Specification: |

D Style Bucket D Style Bucket |

| Model |

A(mm) |

B(mm) |

C(mm) |

D(mm/in) |

E(mm/in) |

No.of holes |

Hole Dia.(mm) |

Capacity(L)(X-Y) |

Capacity(L)(Z-Y)+10% |

Capacity(L)(Z-Y) |

| D4×3 |

107 |

81 |

75 |

22 |

50/63.5 |

2 |

7/6.5 |

0.32 |

0.28 |

0.25 |

| D5×4 |

133 |

113 |

106 |

32 |

60/81 |

2 |

7/6.5 |

0.85 |

0.65 |

0.59 |

| D6×4 |

159 |

108 |

103 |

32 |

90/111.1 |

2 |

7/6.5 |

0.87 |

0.72 |

0.65 |

| D7×4 |

184 |

108 |

103 |

32 |

120/68.3 |

2/3 |

9/6.5 |

1.04 |

0.83 |

0.75 |

| D6×5 |

168 |

140 |

130 |

40/48 |

90/111.1 |

2 |

9/6.5 |

1.48 |

1.21 |

1.1 |

| D7×5 |

192 |

140 |

130 |

40/48 |

120/68.3 |

2/3 |

9/6.5 |

1.73 |

1.32 |

1.2 |

| D8×5 |

211 |

140 |

130 |

40/48 |

120/77.8 |

2/3 |

9/6.5 |

1.92 |

1.55 |

1.41 |

| D9×5 |

237 |

140 |

130 |

40/48 |

85/92.1 |

3 |

9/6.5 |

2.41 |

1.93 |

1.75 |

| D11×5 |

289 |

140 |

130 |

45/48 |

100/76.2 |

3/4 |

9/6.5 |

2.75 |

2.21 |

2.01 |

| D9×6 |

237 |

168 |

154 |

40/50 |

85/92.1 |

3 |

9/6.5 |

3.23 |

2.57 |

2.34 |

| D10×6 |

266 |

168 |

154 |

45/50 |

90/104.8 |

3 |

9/6.5 |

3.62 |

2.84 |

2.58 |

| D11×6 |

287 |

168 |

154 |

45/50 |

100/76.2 |

3/4 |

9/6.5 |

4.01 |

3.11 |

2.83 |

| D12X6 |

313 |

168 |

154 |

45/50 |

85/85.7 |

4 |

9/6.5 |

4.44 |

3.48 |

3.16 |

| D13X6 |

338 |

168 |

154 |

45/50 |

85/92 |

4 |

9/6.5 |

4.74 |

3.78 |

3.44 |

| D14X6 |

368 |

168 |

154 |

50 |

95/76.2 |

4/5 |

9/6.5 |

5.08 |

4.15 |

3.77 |

| D9×6-1/2 |

230 |

180 |

180 |

45 |

75 |

3 |

9 |

3.67 |

2.78 |

2.53 |

| D11×6-1/2 |

280 |

180 |

180 |

45 |

100 |

3 |

9 |

4.62 |

3.52 |

3.2 |

| D10X7 |

269 |

197 |

180 |

50 |

90/104.8 |

3 |

9/8 |

4.83 |

4.07 |

3.7 |

| D11×7 |

287 |

197 |

180 |

45/50 |

100/76.2 |

3/4 |

9/8 |

5.39 |

4.35 |

3.95 |

| D12×7 |

326 |

197 |

180 |

45/50 |

85/85.7 |

4 |

9/8 |

5.81 |

4.79 |

4.35 |

| D13×7 |

343 |

197 |

180 |

45/50 |

90/92 |

4 |

9/8 |

6.52 |

5.58 |

5.07 |

| D14×7 |

373 |

197 |

180 |

50 |

95/76.2 |

4/5 |

9/8 |

6.9 |

5.74 |

5.22 |

| D15×7 |

392 |

197 |

180 |

50 |

100/82.6 |

4/5 |

9/8 |

7.61 |

6.68 |

6.07 |

| D16×7 |

427 |

197 |

180 |

48 |

85/73 |

5/6 |

9/8 |

7.94 |

6.95 |

6.32 |

| D11×8 |

280 |

220 |

216 |

55 |

65 |

4 |

9 |

6.52 |

5.4 |

4.91 |

| D12×8 |

331 |

222 |

206 |

55/60 |

85/85.7 |

4 |

9/8 |

7.45 |

6.35 |

5.77 |

| D12×8-1/2 |

330 |

220 |

216 |

55 |

85 |

4 |

9 |

7.88 |

6.55 |

5.95 |

| D14×8 |

378 |

222 |

206 |

55/60 |

95/76.2 |

4/5 |

9/8 |

8.76 |

7.56 |

6.87 |

| D14×8-1/2 |

380 |

220 |

216 |

55 |

75 |

5 |

9 |

9.24 |

7.69 |

6.99 |

| D15×8 |

392 |

222 |

206 |

55/60 |

80/82.6 |

5 |

9/8 |

9.47 |

8.73 |

7.94 |

| D16×8 |

434 |

222 |

206 |

55/57 |

85/73 |

5/6 |

9/8 |

10.38 |

8.91 |

8.1 |

| D18×8 |

473 |

222 |

206 |

55/60 |

95/79.4 |

5/6 |

9/8 |

11.5 |

9.98 |

9.07 |

| D20×8 |

520 |

225 |

210 |

55/60 |

90/88.9 |

6 |

9/8 |

13.11 |

11.66 |

10.6 |

| D16×9 |

430 |

260 |

260 |

65 |

68 |

6 |

11 |

14.57 |

12.1 |

11 |

Remark: Ⅰ/Ⅱ are drilling modes respectively in metricimperial system. Special drilling can be made as required. |

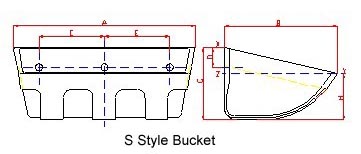

| s series bucket |

|

| Follow the outline structure design of D bucket, it has good features as higher intensity, more wear resistance, extended life span. Compare to D bucket, S bucket with low profile can be installed with less spacing, thus increase the elevator capacity. |

| Usage: |

|

1.Suitable for high-speed elevator light bulk material lifting.

2.Recommended minimum bucket spacing: width of the bucket projection "B"+25mm, which can be appropriately reduced according to elevator capacity requirement.

3.Recommended elevator velocity ≤3.5m/s.

4.Recommend using"Z-Y+5%" as usable capacity for engineering purpose. |

| Specification: |

|

| Model |

A(mm) |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

No. of holes |

Hole Diameter |

Capacity(L)

X-Y |

Capacity(L)

(Z-Y)+5% |

Capacity(L)

Z-Y |

| S1613 |

165 |

135 |

82 |

25 |

90 |

2 |

9 |

0.96 |

0.76 |

0.72 |

| S2314 |

235 |

143 |

96 |

30 |

120 |

2 |

9 |

1.68 |

1.28 |

1.22 |

| S2315 |

235 |

155 |

91 |

30 |

120 |

2 |

9 |

1.78 |

1.49 |

1.42 |

| S2814 |

285 |

143 |

96 |

30 |

90 |

3 |

9 |

2.08 |

1.59 |

1.51 |

| S2815 |

285 |

155 |

91 |

30 |

90 |

3 |

9 |

2.2 |

1.86 |

1.77 |

| S2816 |

290 |

165 |

108 |

35 |

90 |

3 |

9 |

2.65 |

2.31 |

2.2 |

| S2821 |

285 |

219 |

145 |

45 |

100 |

3 |

9 |

5.03 |

3.76 |

3.58 |

| S3216 |

330 |

165 |

111 |

35 |

80 |

4 |

9 |

3.23 |

2.36 |

2.25 |

| S4121 |

420 |

219 |

145 |

45 |

110 |

4 |

9 |

7.58 |

5.7 |

5.42 |

| S5122 |

519 |

225 |

165 |

50 |

100 |

5 |

11 |

11.25 |

9.36 |

8.91 |

Remark: Drilling can be made according to customers’ demand. |

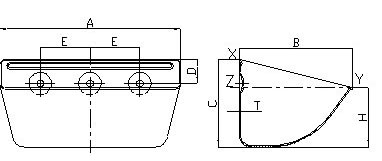

| d type steel bucket |

| Usage: |

|

1.Suitable for high-speed centrifugal discharge.

2.Recommended minimum bucket spacing: width of the bucket projection "B"+25mm, which can be appropriately reduced according to elevator capacity requirement.

3.Recommended elevator line speed ≤2.5m/s.

4.Recommended using “(Z-Y)+10%” as the available capacity for engineering design. |

| Specification: |

Deep style Deep style |

| Model |

A(mm) |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

No. of Holes |

Dia. of Holes |

Capacity(L)

(X-Y) |

Capacity (L)

(Z-Y)10% |

Capacity(L)

(Z-Y) |

| D0808 |

85 |

80 |

58 |

16 |

43 |

2 |

8 |

0.21 |

0.19 |

0.18 |

| D1009 |

106 |

89 |

66 |

20 |

50 |

2 |

9 |

0.33 |

0.28 |

0.25 |

| D1312 |

138 |

120 |

88 |

25 |

70 |

2 |

9 |

0.82 |

0.7 |

0.64 |

| D1612 |

169 |

130 |

124 |

35 |

100 |

2 |

9 |

1.31 |

0.98 |

0.89 |

| D1614 |

166 |

147 |

112 |

30 |

100 |

2 |

9 |

1.58 |

1.32 |

1.2 |

| D1814 |

187 |

147 |

112 |

30 |

100 |

2 |

9 |

1.77 |

1.52 |

1.38 |

| D2314 |

233 |

147 |

112 |

32 |

120 |

2 |

9 |

2.3 |

1.96 |

1.78 |

| D2814 |

288 |

147 |

112 |

32 |

100 |

3 |

9 |

2.91 |

2.49 |

2.26 |

| D2015 |

205 |

150 |

112 |

32 |

100 |

2 |

9 |

2 |

1.68 |

1.53 |

| D2316 |

233 |

160 |

122 |

32 |

70 |

3 |

9 |

2.7 |

2.31 |

2.1 |

| D2616 |

262 |

165 |

130 |

35 |

80 |

3 |

11 |

3.28 |

2.81 |

2.55 |

| D2816 |

288 |

165 |

130 |

38 |

80 |

3 |

10.5 |

3.64 |

3.1 |

2.82 |

| D3016 |

308 |

165 |

135 |

36 |

100 |

3 |

9 |

3.88 |

3.2 |

2.9 |

| D3316 |

340 |

165 |

135 |

38 |

110 |

3 |

11 |

4.4 |

3.85 |

3.5 |

| D3516 |

360 |

165 |

135 |

38 |

89 |

4 |

11 |

4.5 |

4.02 |

3.65 |

| D2818 |

290 |

182 |

140 |

38 |

80 |

3 |

11 |

4.5 |

3.85 |

3.5 |

| D3018 |

308 |

182 |

140 |

36 |

100 |

3 |

9 |

4.5 |

3.85 |

3.5 |

| D3318 |

340 |

182 |

140 |

38 |

110 |

3 |

11 |

5.2 |

4.4 |

4 |

| D3518 |

362 |

182 |

140 |

38 |

120 |

3 |

11 |

5.5 |

4.51 |

4.1 |

| D3718 |

385 |

195 |

140 |

38 |

89 |

4 |

11 |

6.4 |

5.39 |

4.9 |

| D3021 |

310 |

218 |

163 |

50 |

100 |

3 |

11 |

6.7 |

5.72 |

5.2 |

| D3321 |

340 |

215 |

163 |

50 |

120 |

3 |

11 |

7.2 |

6.22 |

5.65 |

| D3521 |

362 |

215 |

162 |

50 |

120 |

3 |

11 |

7.6 |

6.45 |

5.86 |

| D3721 |

384 |

215 |

160 |

50 |

89 |

4 |

11 |

8.6 |

7.13 |

6.48 |

| D4521 |

464 |

215 |

163 |

50 |

89 |

5 |

11 |

10.1 |

8.47 |

7.7 |

| D5021 |

515 |

215 |

163 |

50 |

100 |

5 |

11 |

11.25 |

9.8 |

8.91 | |

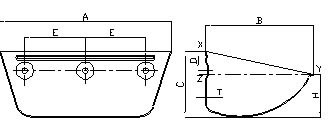

| s type steel bucket |

| With more small bucket spacing compared with D type bucket, to increase the elevator capacity. |

| Usage: |

|

1.Suitable for high-speed elevator light bulk material lifting.

2.Recommended minimum bucket spacing: width of the bucket projection "B", which can be appropriately reduced according to elevator capacity requirement.

3.Recommended elevator line speed ≤3.5m/s.

4.Recommended using “(Z-Y)+5%” as the available capacity for engineering design. |

| Specification: |

(fleet style) (fleet style) |

| Model |

A(mm) |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

No. of Holes |

Dia. of Holes |

Capacity(L)

(X-Y) |

Capacity (L)

(Z-Y)5% |

Capacity(L)

(Z-Y) |

| S1009 |

106 |

89 | ,

62 |

20 |

50 |

2 |

9 |

0.29 |

0.2 |

0.19 |

| S1312 |

140 |

114 |

78 |

22 |

70 |

2 |

9 |

0.61 |

0.43 |

0.41 |

| S1814 |

187 |

140 |

92 |

28 |

100 |

2 |

9 |

1.29 |

0.95 |

0.9 |

| S2314 |

237 |

140 |

92 |

28 |

120 |

2 |

9 |

1.7 |

1.33 |

1.26 |

| S2316 |

238 |

165 |

108 |

35 |

120 |

2 |

9 |

2.25 |

1.73 |

1.65 |

| S2814 |

287 |

140 |

92 |

28 |

90 |

3 |

9 |

2.11 |

1.64 |

1.56 |

| S2816 |

289 |

165 |

108 |

38 |

80 |

3 |

11 |

2.91 |

2.18 |

2.08 |

| S3018 |

308 |

182 |

117 |

35 |

100 |

3 |

11 |

3.66 |

2.58 |

2.46 |

| S3316 |

330 |

165 |

108 |

38 |

100 |

3 |

9 |

3.3 |

2.53 |

2.41 |

| S3021 |

310 |

217 |

140 |

38 |

100 |

3 |

11 |

5.5 |

4.2 |

4 |

| S3321 |

340 |

214 |

130 |

38 |

120 |

3 |

11 |

5.51 |

4.11 |

3.92 |

| S3721 |

384 |

214 |

130 |

38 |

89 |

4 |

11 |

6.18 |

4.39 |

4.18 |

| S4521 |

464 |

214 |

130 |

38 |

89 |

5 |

11 |

8 |

5.87 |

5.59 |

| S4626 |

465 |

260 |

170 |

50 |

95 |

5 |

11 |

10.7 |

7.35 |

7 |

| S5626 |

565 |

265 |

170 |

50 |

110 |

5 |

11 |

15 |

11 |

10.5 | |